Recursos Universitários

Colaborações

Emprego Qualificado

Atividades de I+D+i

Rede Institucional

Competitividade

Estamos aberto a pequenas, médias e grandes empresas que pretendam tornar-se mais competitivas.

Espaços para Laboratórios

O PCT “Brigantia-Ecopark” está preparado para acolher laboratórios na atividade principal das áreas estratégicas.

O edifício principal possui 23 espaços modulares para laboratórios com quatro principais tipologias:

- 10 espaços com 56 m2

- 4 salas com 40 m2

- 8 espaços com 50 m2

- 1 espaço desenvolvidos em altura com 110 m2

Distribuídos pelo nível 1 e nível 2, estes espaços são modulares e podem ser adaptados às necessidades das empresas e do PCT.

Equipamentos

GENERAL CLUSTER

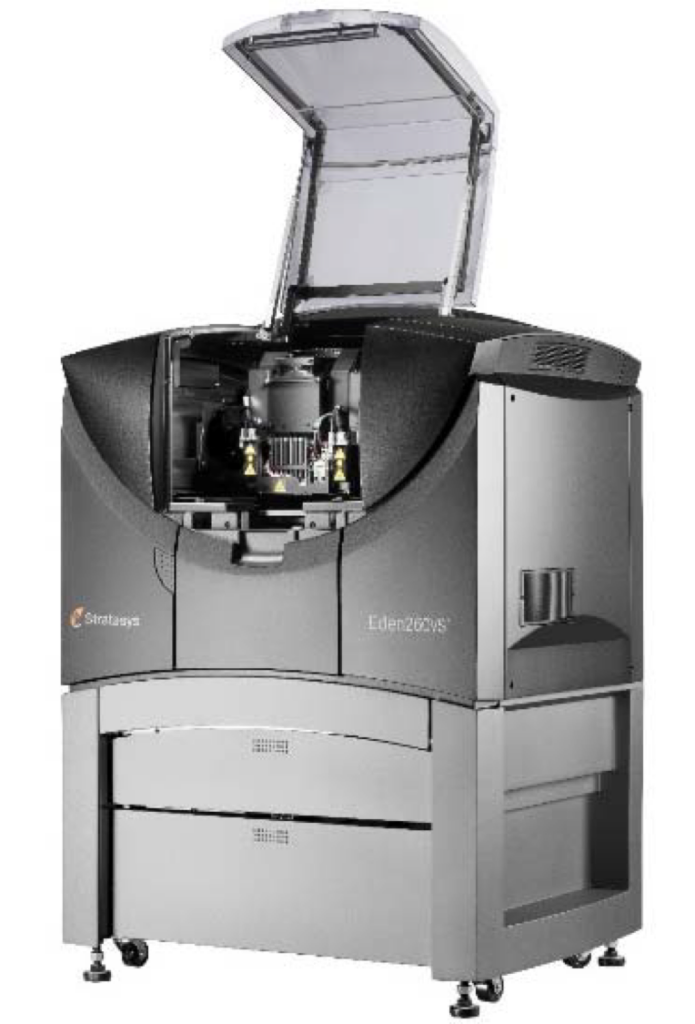

3D RAPID PROTOTYPING

Rapid Prototyping is able to provide fast turnaround 3D printing and sample prototyping services for internal and external tech base companies. 3D printing or rapid prototyping will facilitate the production of new or modified products directly from 3D designs. This drastically changes conventional business models by extending the boundary of design and production to quickly respond to the dynamic change in customer demands.

Objet Eden professional 3D printers work with 15 materials to deliver outstanding precision and productivity, including: Transparent materials for producing clear models with great dimensional stability and surface smoothness, rigid opaque materials (Vero family) in a variety of colors including white, gray, blue and black, Simulated Polypropylene materials with toughness and durability to create smooth prototypes with living hinges, flexible closures and snap-fit parts, Rubber-like materials (Tango family) suitable for a range of applications requiring non-slip or soft surfaces, High Temperature (RGD525) for advanced functional testing, hot air and water flow, and static applications (models with thermal resistance and dimensional stability).

This model (Stratasys Eden260V) is the first system to offer PolyJet technology with soluble support. Automated support removal reduces hands-on labour and reaches internal voids that water-jetting can miss, making it ideal for models with delicate features or hard-to-reach cavities.

The Objet Eden260VS builds parts directly from digital files two times faster than other lowest-priced PolyJet solution. Plus, it takes workflow automation a step further with soluble support material that dissolves easily from tiny cavities, overhangs and crevasses.

| ODEL | Object EDEN260VS – STRATASYS |

| NET BUILD SIZE LAYER THICKNESS BUILD RESOLUTION ACCURACYWORKSTATION COMPATIBILITY NETWORK CONNECTIVITY SIZE AND WEIGHT JETTING HEADS POWER REQUIREMENTS OPERATIONAL ENVIRO. TEMPERATURE OPERATIONAL ENVIRO. RELATIVE HUMIDITY |

255 × 252 × 200 mm Horizontal build layers as fine as 16 microns X-axis: 600 dpi; Y-axis: 600 dpi; Z-axis: 1600 dpi 20-85 microns for features below 50 mm; up to 200 microns for full model size (for rigid materials only, depending on geometry, build parameters and model orientation) Windows 7 32/64-bit LAN – TCP/IP 870 × 735 × 1200 mm; 264 kg SHR (Single Head Replacement) 8 units 110–240 VAC 50/60 Hz; 1.5 KW single phase 18 C-25 C 30-70% |

ADVANCED MONITORING AND CONTROL FOR LABORATORIES

LABORIAL advanLab® is a centralized automation system for laboratories that integrates the core needs of monitoring and control existing in these areas: operating parameters, safety, energy, air quality control and maintenance. A part of the system consists in a software which allows users monitoring and control of different variables/parameters of the equipments, laboratory rooms, floors and the whole building in real time, and intuitively. This software allows setting different limits of alarms for each variable, establishing how to alert the user in the case of alarm (SMS, email, visual or audible), view parameters’ graphics and statistic data, and export data in many formats (.csv, .pdf, .doc, .xls). The other part of the system, which allows data acquisition and actuation, consists in a network of transmitters with wireless communication and powered by battery.

Sensors should be applied in 3 shared laboratories using for each laboratory: 2 temperature probes, 1 humidity sensor, 1 gas detector sensors (CO2), 1 air quality sensor and 1 Sensor detection of water leaks, 3 sensors power consumption control by existing electrical equipment.

UNIVERSAL TESTING MACHINE

The universal machine INSTRON 3382 floor model, testing system is suited for tension, compression, peel, flex, and other applications with maximum testing load up to 100 kN.

The universal machine INSTRON 3382 has: Automatic recognition and calibration of load and strain transducers, Preloaded ballscrews, precision guidance columns, and a symmetrical drive, Extensive range of accessories to meet test requirements in almost any application or industry: plastics, metals, biomedical, composites, elastomers, components, automotive, aerospace, textiles, and more; Self-diagnostics expedite troubleshooting and minimize downtime.

The universal machine INSTRON 3382 has force measurement accuracy: meets or exceeds the following standards: ASTM E-4, BS 1610, DIN 51221, ISO 7500/1, EN 10002-2, JIS B7721, JIS B773 e AFNOR A03-501.

The universal machine INSTRON 3382 has strain measurement accuracy: meets or exceeds the following standards: ASTM E-83, BS 3846, ISO 9513 and EN 10002-4.

The universal machine INSTRON 3382 pickup data with sampling rate of 40KHz and transfers to computer at 500Hz with 4 channels synchronously.

The universal machine INSTRON 3382 has grips for tensile and compressive testing. Grips for rectangular samples up to 12 mm thickness, 50mm x 0-6mm, 50 X 6-12mm. Grips for circular samples up to 7 – 12,7mm, and 12,7 – 19mm. Plates for compressive testing with diameter up to 150 mm. Accessory for three and four bending points, using roller bearing supports with 10 mm.

The universal machine INSTRON 3382 has also a computer program (BLUEHILL LE) to help analyse the experimental results.

| MODEL | INSTRON 3382 |

| LOAD CAPACITY MAXIMUM SPEED MINIMUM SPEED MAXIMUM FORCE AT FULL SPEED MAXIMUM SPEED AT FULL LOAD RETURN SPEED TOTAL CROSSHEAD TRAVEL TOTAL VERTICAL TEST SPACE SPACE BETWEEN COLUMNS HEIGHT WIDTH DEPTH WEIGHT WITH TYPICAL LOAD CELL MAXIMUM POWER REQUIREMENT VA 1,500 |

100 kN 500 mm/min 0.005 mm/min 50 kN 250 mm/min 600 mm/min 1235 mm 1323 mm 575 mm 2393 mm 1124 mm 779 mm 766 kg 1 phase |

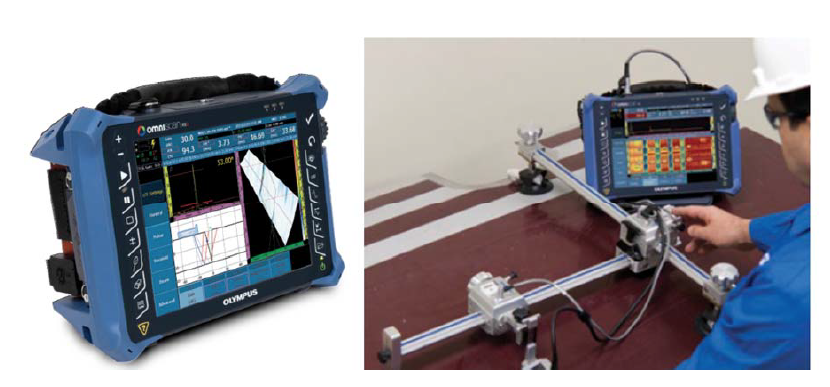

PHASED ARRAY FLAW DETECTOR

The OLYMPUS OMNISCAN MX2 is an important part of your inspection solution, and can be combined with other critical components to form a complete inspection system. Olympus offers a complete product range that includes phased array probes, scanners, analysis software, and accessories, all of which are integrated and packaged into rapidly deployable, application-specific solutions.

The OLYMPUS OMNISCAN MX2 typical Application is Weld Inspection. These phased array systems, which are certified for tube inspection in compliance with ASME, API, and other code criteria, offer superior inspection speed and detection, and facilitate interpretation of indications.

The OLYMPUS OMNISCAN MX2 is compatible with standard industry inspection codes, including, but not limited to: ASME Section V Article 4, All ASME phased array code cases, ASTM E2700-09, ASTM E2491-06, AWS, API 1104 and API RP2X, CEN EN 583-6, BSI BS7706 … and more.

The OLYMPUS OMNISCAN MX2 works with the following probes: Standard Phased Array Probe, 5 MHz Linear Array, 16 Elements, 9.6×10 mm Total Active Aperture, 0.60 mm Pitch, 10 mm Elevation; Standard Phased Array Probe, 1 O MHz Linear Array, 32 Elements, 9.9×7 mm Total Active Aperture, 0.31 mm Pitch, 7 mm Elevation; Standard wedge for phased-array probe A 1O, normal scan, 0-degree longitudinal wave, plain wedge; Standard wedge for phased-array probe A10, normal scan, 55-degree shear wave, plain wedge.

| MODEL | OLYMPUS OMNISCAN MX2 |

| OVERALL DIMENSIONS (W X H X D) WEIGHT STORAGE DEVICES DATA FILE SIZE USB PORTS SPEAKER OUT VIDEO OUTPUT ETHERNET ENCODER DIGITAL INPUT DIGITAL OUTPUT ACQUISITION ON/OFF SWITCH POWER OUTPUT LINE ALARMS ANALOG OUTPUT PACE INPUT DISPLAY SIZE DISPLAY RESOLUTION DISPLAY BRIGHTNESS DISPLAY NUMBER OF COLORS DISPLAY TYPE BATTERY TYPE NUMBER OF BATTERIES BATTERY LIFE OPERATING TEMPERATURE RANGE STORAGE TEMPERATURE RANGE RELATIVE HUMIDITY SHOCKPROOF RATING |

325 mm x 235 mm x 130 mm 5 kg including module and one battery SDHC card, most standard USB storage devices, or fast Ethernet 300 MB 3 Yes Video out (SVGA) 10/100 Mbps 2-axis encoder line (quadrature, up, down, or clock/direction) 4 digital TTL inputs, 5 V 4 digital TTL outputs, 5 V, 15 mA Remote acquisition enabled TTL, 5 V 5 V, 500 mA power output line (short-circuit protected) 3 TTL, 5 V, 15 mA 2 analog outputs (12 bits) ±5 V in 10 kΩ 5 V TTL pace input 26.4 cm (10.4 in.) (diagonal) 800 pixels x 600 pixels 700 cd/m² 16 million TFT LCD Smart Li-ion battery 1 or 2 (battery chamber accommodates two hot-swappable batteries) Minimum 6 hours with two batteries 0 °C to 45 °C; 0 °C to 35 °C with 32:128 PA –20 °C to 60 °C with batteries, –20 °C to 70 °C without batteries 0% to 85% noncondensing No air intake; designed for IP66 Drop-tested according to MIL-STD-810G 516.6 |

3D COORDINATE MEASURING SYSTEM AND SHAPE SURVEY FOR REVERSE ENGINEERING

The CREAFORM HANDYPROBE C-TRACK 780 arm-free probing system generates high-accuracy measurements (accuracy of up to 22 µm), and outperforms traditional portable Coordinate Measuring Machine (CMM) on the shop floor. The CREAFORM HandyPROBE portable CMM is currently used on the production lines of major players from the automotive, aerospace and manufacturing industries.

The CREAFORM HANDYPROBE C-TRACK 780 is: insensitive to changes in the environment (vibrations, part displacement, set-up or CMM instability have no impact); highly efficient at measuring parts that can’t be moved to a granite or cast iron table; ideal for geometric and surface quality control, it offers scanning capabilities when paired with a MetraSCAN 3D scanner; Part size range: 1-3 meters, any type of materials; Extendable measurement range up to 10 m; Truly portable and wireless.

The CREAFORM METRASCAN 210 offers increased measurement speed with equal accuracy. Its increased stand-off and depth of field make for enhanced scanning flexibility. It is ideal for large surface metrology and large-scale reverse engineering.

The software METROLOG X4 EVO (PACK OPTIC ARM GEOSURF ADVANCED) is the ideal software for a real performance accelerator for 3D measuring devices. This software is able to import huge and complex CAD models for direct analysis of measurement data to nominal CAD data, “live-scan” and/or import huge point cloud data files with no deterioration in processing speed and significantly reduce conversion and projection time while using large data sets.

| MODEL | CREAFORM HANDYPROBE C-TRACK 780 |

| ACCURACY SINGLE POINT REPEATABILITYVOLUMETRIC ACCURACYMEASUREMENT SPEED WEIGHT DIMENSIONS OPERATING TEMPERATURE RANGE OPERATING HUMIDITY RANGE CERTIFICATIONS |

Up to 0.025 mm 0.050 mm in 3.80 m³ 0.055 mm in 7.80 m³ 0.080 mm in 3.80 m³ 0.085 mm in 7.80 m³ 30 Hz 5,5 kg (12 lbs.) 1035 x 169 x 140 mm (40.8 x 6.6 x 5.5 in.) 5–40 °C (41-104 °F) 10–90 % EN 301 489-1, EN 301 489-3, EN 300 220-1 |

| MODEL | CREAFORM METRASCAN 210 |

| WEIGHT DIMENSIONS MEASUREMENT RATE VOLUMETRIC ACCURACY (WITH C-TRACK 780) RESOLUTION STAND-OFF DISTANCE DEPTH-OF-FIELD LASER CROSS AREA OPERATING TEMPERATURE RANGE OPERATING HUMIDITY RANGE CERTIFICATIONS |

1.85 kg (4 lbs) 282 x 250 x 282 mm (11 x 9.8 x 11 in.) 36,000 measures /sec. 0.085 mm 0.1 mm (0.004 in.) 300 mm (12 in.) ± 100 mm 210 mm x 210 mm (8.2 x 8.2 in.) 5-40 °C (41-104 °F) 10-90% EN 301 489-1, EN 301 489-3, EN 300 220-1 |

SERVICES FOR THE CLUSTER OF NATURAL PRODUCTS

R&D SOLUTION FOR SPRAY DRYING

The Mini Spray Dryer B-290 advanced BUCHI is designed to visualize the Spray Drying process for wide range of applications in various fields such as pharma, materials, chemistry, food, feed, beverages, etc. It allows working with acids, organic solvents or mixtures of aqueous and organic solvents safely in combination with the Inert Loop B-295 and the Dehumidifier B-296.

The Inert Loop is the perfect accessory to enable the Mini Spray Dryer B-290 to handle organic solvents safely. Furthermore, it conserves resources and environment due to its functional principle.

The Dehumidifier B-296 is the ideal accessory to condition the drying air or to work continuously with water and organic solvent mixtures. It ensures process stability and performance.

|

|

|

PARTICLE SIZE MEASUREMENTS

The MALVERN MASTERSIZER 3000 is the latest generation of the world’s most widespread particle sizing instrument, used by many thousands of companies and research institutes across a wide range of industries.

The MALVERN MASTERSIZER 3000 has a new optical core design and delivers fast measurement times for high sample throughput and a measurement size range from 10nm to 3.5mm. The MALVERN MASTERSIZER 3000 uses the technique of laser diffraction to measure particle size. Sample dispersion is controlled by a range of wet and dry dispersion units (Medium sample volume – HYDRO MV). This ensure the particles are delivered to the measurement area of the optical bench at the correct concentration and in a suitable, stable state of dispersion to make accurate and reliable particle size measurements.

| MODEL | MALVERN MASTERSIZER 3000 |

| MATERIALS DATA ACQUISITION RATE TYPICAL MEASUREMENT TIME RED LIGHT SOURCE BLUE LIGHT SOURCE LENS ARRANGEMENT EFFECTIVE FOCAL LENGTH ARRANGEMENT ANGULAR RANGE ALIGNMENT SIZE RANGE NUMBER OF SIZE CLASSES ACCURACY REPEATABILITY REPRODUCIBILITY SOFTWARE LASER CLASS OPTICS DIMENSIONS SUPPLY VOLTAGE PRODUCT STORAGE TEMPERATURE OPERATIONAL TEMPERATURE RANGE |

Suspensions, emulsions, dry powders 10kHz <10 sec Max. 4mW He-Ne, 632.8nm Nominal 10mW LED, 470nm Reverse Fourier (convergent beam) 300mm Log-spaced array 0.015 – 144 degrees Automatic 0.01 – 3500µm (sample preparation dependent) 100 (user adjustable) Better than 1% Better than 0.5% variation Better than 1% variation 21 CFR part 11 Class 1 690mm x 300mm x 450mm (L x W x H) 100/240v, 50/60Hz -20 °C to +50 °C +5 °C to +40 °C |

PROFESSIONAL ULTRASONIC CLEANER

Bandelin Sonorex Super RK100(H) is a professional ultrasonic cleaner, working with heating (RK100H) and 320 Watt ultrasonic power. Stainless steel tank with 3 litre capacity. Internal tank dimensions: 240 x 140 x 100 mm.

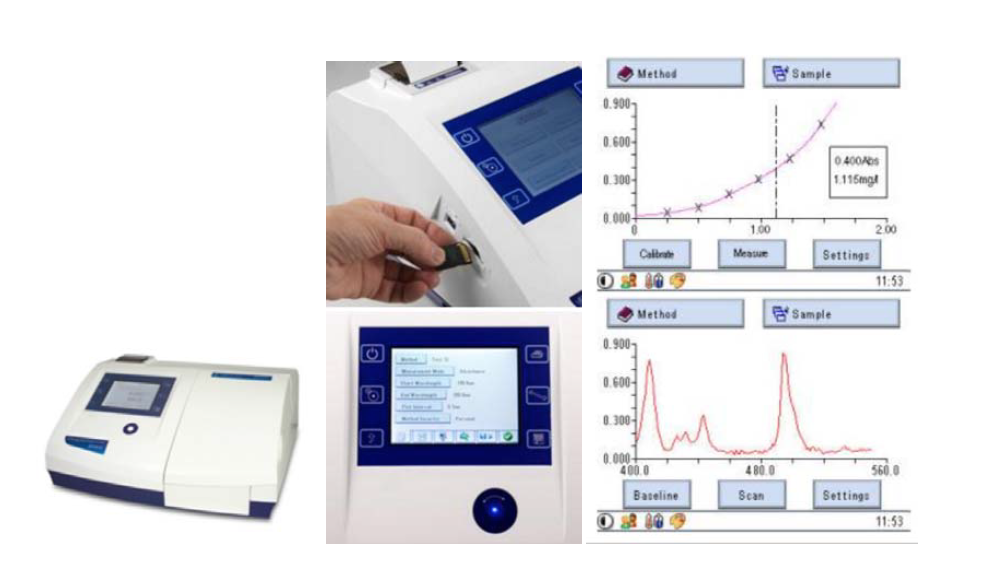

VISIBLE AND UV/VISIBLE SCANNING SPECTROPHOTOMETER

JENWAY 6705 SPECTROPHOTOMETER has modes for photometrics, spectrum scanning, multi-wavelength analysis, kinetics and quantitation, giving direct concentration results against single or multi-point calibrations. With extensive post measurement tools to ensure results are presented exactly to each user’s requirements JENWAY 6705 SPECTROPHOTOMETER also offers significant advances in data portability. Together, the touch screen and colour display give the fastest, most flexible instrument interface possible. Where fine cursor control is required, using the QWheel™ makes the task easy and precise.

| MODEL | JENWAY 6705 SPECTROPHOTOMETER |

| LIGHT SOURCE OPTICS SPECTRAL BANDWIDTH STRAY LIGHT WAVELENGTH RANGE (NM) WAVELENGTH RESOLUTION (NM) WAVELENGTH ACCURACY (NM) WAVELENGTH REPEATABILITY (NM) PHOTOMETRIC RANGES PHOTOMETRIC RESOLUTION PHOTOMETRIC ACCURACY PHOTOMETRIC STABILITY CONCENTRATION RANGE NO OF STANDARDS CURVE FIT ALGORITHMS MULTI-WAVELENGTH DATA POINTS CALCULATIONS KINETICS TIME LIMITS KINETICS CALIBRATION SCAN SPEED POST SCAN ANALYSIS CONFIGURATION NO OF USERS NO OF METHODS RESULTS STORAGE FILE OUTPUT REMOVABLE MEDIA INTERFACE PC SOFTWARE MAINS SUPPLY SIZE WEIGHT |

Xenon Sealed, MgF Coated, Split Beam 4nm 0.05%T at 220nm 190 to 1100 0.1 ±1.0nm ±0.2nm 0.300 to 3.000A & 0 to 199.9%T 0.001A & 0.1%T ±0.005 at 1A <0.001A per Hour Up to 99999 20 with up to 5 replicates of each Linear, Quadratic and Cubic Functions Up to 4 Wavelengths Difference and ratio 0 to 9999 Secs Standard or factor 1500nm/minute at 0.1nm data steps Peak/Valley pick, Area, Zoom, Wavelength Table, Overlays, Derivatives, Smoothing Secure Multi-User or Free access 10 + Supervisor >1000 at 256MB, >10000 at 2GB internal memory >1000 at 256MB, >10000 at 2GB internal memory CSV or BMP SD, SD/USB & MM memory card SD. Options from 256MB to 2GB USB, Centronics, Analogue Supplied on CD ROM with USB Interface Cable 100 to 230V ac 50 or 60Hz 490 x 390 x 220 mm 9.0Kg |

ROTARY EVAPORATOR WITH VACUM PUMP

The rotary evaporator HEIDOLPH – HEI-VAP ADVANTAGE HL GLASSWARE G3 VERTICAL is a device normally used in chemical laboratories for the efficient and gentle removal of solvents from samples by evaporation. Rotary evaporators are also used in molecular cooking for the preparation of distillates and extracts. The rotary evaporator HEIDOLPH – HEI-VAP ADVANTAGE HL GLASSWARE G3 VERTICAL includes leading safety standards and features for superior ease of use and is available in hand lift.

|

The vacuum pump ROTAVAC VALVE TEC is a two-stage diaphragm vacuum pump made of Chemical-resistant material, Recommended for solvents with low or medium boiling points. The vacuum is controlled manually and presents the following characteristics.

| MODEL | ROTAVAC VALVE TEC |

| SUCTION CAPACITY ACHIEVES AN ULTIMATE VACUUM OF CAN BE COMBINED WITH A CONDENSER POWER INPUT: WEIGHT: DIMENSIONS (WITHOUT CONDENSER): |

0.75 m3/h 12 mbar yes 80 W 6.0 kg L145 / W315 / H169 mm |

ABSORBANCE MICROPLATE READER

The microplate reader BIOTEK ELx80 is designed for applications within the clinical, biotechnology research and pharmaceutical laboratory. It is an ideal solution for many microplate based biological assays. The ELx800 can be controlled by Gen5 software, expanding the reader’s capabilities to include kinetics and well area scanning measurements. Gen5 offers unsurpassed data reduction capability as well as customizable data output options.

| MODEL | BIOTEK ELx80 |

| DETECTION MODES READ METHODS MICROPLATE TYPES SOFTWARE ONBOARD SOFTWARE LIGHT SOURCE WAVELENGTH SELECTION WAVELENGTH RANGE BANDWIDTH DYNAMIC RANGE RESOLUTION FILTER WHEEL CAPACITY FILTERS SUPPLIED OD ACCURACY OD LINEARITY OD REPEATABILITY READING SPEED POWER DIMENSIONS WEIGHT |

Absorbance End point, kinetic and area scanning under computer control 6- to 384-well plates, 60/72/96-well Terasaki plates (NB option) Gen5 Data Analysis Software optional 55 user-programmable protocols Tungsten AND halogen Filters 400 to 750 nm, 340 to 750 nm (UV option) 10 nm 0 to 3.0 OD 0.001 OD 5 positions 4 filters (5 with UV option) <1% at 2.0 OD <1% at 2.0 OD, < 3% at 3.0 OD <0.5% at 2.0 OD 96 wells: 30 seconds 100 – 240 Volts AC. 50/60 Hz. 15″W x 16.5″D x 7″H (38.1 x 41.9 x 17.8 cm) 18.5 lbs (8 kg) |

COMBINED SYSTEM FOR ULTRA PURE WATER AND DEIONIZED

The Labconco WATERPRO PS HPLC/UF HYBRID SYSTEM WITH DISPENSING GUN is a Polishing Stations deliver Type I, 18.2 megohm-cm water from the dispensing valve or optional dispensing gun at a typical rate of 1.8 liter per minute depending on feed water flow rate and pressure, and installed purification modules. The control panel includes a timed dispense feature that allows unattended dispensing of pure water without risk of overfilling. The dispenser shuts off automatically once user-set time has elapsed.

Labconco has designed WaterPro PS Stations with the right combinations of purification technologies and this version has also a Polishing Kit.

PREPARATIVE SYSTEM FOR CHROMATOGRAPHY SEPAR. AND PURIF. OF SAMPLES

The knauer AZURA PREPARATIVE HPLC SYSTEM is a complete binary high pressure gradient (HPG) HPLC system for the purification of samples in the laboratory scale. The AZURA Preparative HPLC system is designed and optimized for the purification of milligram to gram samples. The system proposal consists of two preparative HPLC pumps, a UV/VIS detector and a freely customizable combination module.

The knauer AZURA P 2.1L PUMP covers a wide flow rate range and pressure capabilities. In the current setup, it supports max. pressures up to 225 bar at flow rates up to 100 ml/min (200 bar from 150 ‐ 250 ml/min). The integrated automatic recognition of the pump head with RFID technology allows fast adaptions of the pump for various applications. The HPG setup enables the precise formation of binary gradients. Besides, ternary and quaternary gradients are accessible by integration of additional preparative pumps.

C18 PREPARATIVE COLUMN CHROMATOGRAPHY (SILICA)

Based on an ultra pure spherical silica gel, knauer EUROSPHER II is a high performance column material for analytical, semipreparative and process-scale applications. Eurospher II features very narrow particle and pore size distributions, as well as outstanding mechanical stability. Eurospher II silica gel is perfectly suited to take on routine analyses as well as the most ambitious chromatography tasks.

The new knauer EUROSPHER II C18 generation possesses all of the excellent properties a new generation stationary phase can offer and can nearly solve every separation problem. The C18 modification is most suitable for acidic, basic and neutral analytes in reversed phase mode (sulphonamides; anabolic steroids; anti-psychotics; beta blocker; Sudan dyes; phenols, preservatives etc.).

| MODEL | KNAUER EUROSPHER II C18 |

| MODIFICATION SPECIAL CHARACTERISTICS PORE SIZE PARTICLE SIZE LENGTH INNER DIAMETER |

C18 endcapped 100 Å 20-45 µm 250 mm 30 mm |

DEEP-FREEZING CHAMBER

The Arctiko ULUF 450 -86°C range is a deep freezing chamber, striving for excellence in ultra low temperature freezing. All features such as alarms and data logging functions are always included. The ULUF -86°C series is produced with the true and original single compressor technology.

| MODEL | ARCTIKO ULUF 450 DAI 1408 |

| DIMENSIONS EXTERIOR WXDXH (MM): CAPACITY (L): DIMENSIONS INTERIOR WXDXH (MM): INSULATION (MM): TEMPERATURE RANGE (°C): MAX. AMBIENT TEMPERATURE (°C): POWER SUPPLY (V): FREQUENCY (HZ): POWER CONSUMPTION (KWH/24H): |

720x885x2089 413 480x608x1415 120 -86 / -40 25 230 50/60 14,9 |

LABORATORY CENTRIFUGE HIGH CAPACTY BENCH TOP

The Centurion Scientific BENCHTOP CENTRIFUGES K243 delivers efficient sample processing in clinical protocols, cell culture applications, microplate processing and a variety of separation needs.

The Centurion Scientific BENCHTOP CENTRIFUGES K243 is available with Centurion Scientific SWING OUT ROTORS BRK5553.

|

LABORATORY FREEZE DRYER

The Zirbus LYOPHILIZERS VACO 10-II-D presents the ultimate technology in freezing and drying foods, pharmaceuticals and technical products.

| MODEL | ZIRBUS LYOPHILIZERS VACO 10-II-D |

| DIMENSIONS OF CONDENSER VOLUME TEMPERATURE OF CONDENSER ICE CAPACITY MAX. ICE CAPACITY COOLING SYSTEM OUTER DIMENSIONS (WXHXD) WEIGHT ELECTICAL CONNECTION |

Ø 400 x 400 mm 50 liter -80°C 10kg/24h 12 kg two-stage, free of CFC 800x1200x650mm 90 kg 230 V, 50/60 Hz |

PRESSURE REACTOR

The Parr REACTOR 4581 is normally used in many branches of chemical technology. Catalytic Hydrogenation with its associated catalyst development and testing is certainly one of the principal applications of these reactors with their excellent three phase mixing designs. Polymer development is another major area of application. Additionally, the vessels have been used extensively in hydrometallurgical applications.

The Parr REACTOR 4581 presents the capacity of 3.75 L and is designed for 3000 psi (200 bar) maximum pressure with a 500 °C maximum working temperature and mounted on movable carts.

| MODEL | PARR REACTOR 4581 |

| REACTOR MOUNTING SIZES, ML MAXIMUM PRESSURE, MAWP MAXIMUM TEMPERATURE WITH FG FLAT GASKET VESSEL DETAILS:CLOSURE (CAP SCREWS) VALVES MOUNTED VALVE CONNECTIONS MAGNETIC STIRRER, MODEL NO. MAXIMUM TORQUE IMPELLER(S), 6-BLADE (4-BLADE) PRESSURE GAGE, SIZE RANGE TEMPERATURE MEASUREMENT COOLING COIL STYLE BOTTOM DRAIN VALVE HEATER STYLE HEATER POWER, WATTS STIRRER MOTOR, VARIABLE SPEED ELECTRICAL SUPPLY:VOLTS, AC MAXIMUM LOAD, AMPS, 115 / 230 VESSEL DIMENSIONS: INSIDE DIAMETER, INCHES INSIDE DEPTH, INCHES WEIGHT OF MOVEABLE VESSEL, POUNDS WEIGHT OF FIXED VESSEL, POUNDS REACTOR DIMENSIONS :MOVEABLE WIDTH X DEPTH X HEIGHT, IN. FIXED WIDTH X DEPTH X HEIGHT, IN. MOVEABLE WEIGHT W/CONTROLLER, POUNDS FIXED WEIGHT W/CONTROLLER, POUNDS |

Cart / Floor Stand 3750 3000 psi (200 bar) 500 °C Split Ring (16) Head 1/4″ NPT Female A1180HC 60 Inch-Pounds 2 (3.5″ dia.) 4.5 inches 0-5000 psi (345 bar) Thermowell Included Serpentine A177VB Ceramic 2800 1/2 hp 230 15 5.5 9.7 100 120 Cart: 35 x 18 x 50 Floor Stand: 20 x 33 x 75 325 345 |

MAGNETIC STIRRING SYSTEM, HEATING AND REFLUXING

The Paralab MAGNETIC STIRRING SYSTEM, HEATING AND REFLUXING works with cooling water for 6 samples atmosphere (adaptable to 6 round bottom flasks with 25 volumes (100 ml and 250 ml).

The Paralab MAGNETIC STIRRING SYSTEM, HEATING AND REFLUXING allows to program the temperature more closely and consistently. With this magnetic stirring system, simultaneous agitation and heat is achieved to keep plating solution homogenous.

MODELPARALAB MAGNETIC STIRRING SYSTEM

MAGNETIC STIRRING up to 1400 rpm

DIGITAL TEMPERATURE CONTROLLER room temperature with ± 0.5 °C accuracy

SERVICES FOR THE CLUSTER OF ENERGY AND ECOMATERIALS

RAPID PCB PROTOTYPING

The LPKF ProtoMat S103 circuit board plotter for producing PCB prototypes and small batches is configured specifically for RF and microwave requirements. The touchless, pneumatic depth limiter further allows delicate surfaces, soft and flexible substrates to be processed. The ProtoMat S103 also carefully depanels irregular shaped flexible circuit boards from larger boards.

The sophisticated Z-axis drive makes the ProtoMat S103 perfect for finishing front panels and housings as well as depth milling microwave PCBs. Even machining populated PCBs is no problem at all.

The ProtoMat S103 is extremely fast and accurate with a spindle speed of 100.000 rpm, a max. travel speed of 150 mm/s and a resolution of 0.5 μm. This ensures the accuracy required for drilling and milling ultra fine structures – especially for high-end applications in the RF- and microwave field.

CircuitPro turns raw CAD data into a dataset for populating the circuit board with soldering paste with no additional expense. The software wizard guides the user through the individual process steps. An internal computation accounts for the pad shape and size to ensure each pad has the right amount of soldering paste. This is further achieved through proven process parameters. The paste is applied with the built-in dispenser, all without having to convert the machine.

| MODEL | LPKF PROTOMAT S103 |

| MAX. MATERIAL SIZE AND LAYOUT AREA (X/Y/Z) RESOLUTION (X/Y) REPEATABILITY PRECISION OF FRONT-TO-BACK ALIGNMENT MILLING SPINDLE TOOL CHANGE MILLING WIDTH ADJUSTMENT TOOL HOLDER DRILLING SPEED TRAVEL SPEED (X/Y) X/Y-DRIVE Z-DRIVE DIMENSIONS (W X H X D) WEIGHT OPERATING CONDITIONS POWER SUPPLY COMPRESSED AIR SUPPLY |

229 mm x 305 mm x 35/22 mm (9″ x 12″ x 1.4/ 0.9″)* 0.5 µm (0.02 mil) ± 0.001 mm (± 0.04 mil) ± 0.02 mm (± 0.8 mil) Max. 100,000 rpm, software controlled Automatic, 15 positions Automatic 3.175 mm (1/8″), automatic holder 120 strokes/min Max. 150 mm/s (6″/s) 3-phase stepper motor 2-phase stepper motor 670 mm x 540 mm x 840 mm (26.4″ x 21.3″ x 33″) 60 kg (132 lbs)90 – 240 V, 50 – 60 Hz, 450 W 6 bar (87 psi), 100 l/min (3.5 cfm) |

The system is available with the LPKF MiniContac, an electroplating systems for professional through hole platings in PCB prototypes and small batches. This equipment can handle PCBs up to 230 mm x 330 mm (9” x 13”). The system does not require external connections.

| MODEL | LPKF MINICONTAC |

| ACTIVATOR MAX. MATERIAL SIZE MAX. LAYOUT SIZE HOLE DIAMETER NUMBER OF THROUGH-PLATED HOLES MAX. NUMBER OF LAYERS MAX. CONTACT RESISTANCE ENVIRONMENTAL COMPATIBILITY PROCESSING RELIABILITY PROCESSING TIME BASE MATERIAL TYPES AMBIENT TEMPERATURE DIMENSIONS (W X H X D) CHEMICAL TINNING REVERSE PULSE PLATING WEIGHT |

Carbon 230 mm x 330 mm 200 mm x 290 mm 0.2 mm No limit 8 Less than 10 mΩ Very good Very good 90 –120 min FR4, RO3000, RO4000, TMM 18 – 25 °C 750 mm x 525 mm x 500 mm No Yes 42 kg unfilled; 71 kg filled |

Reflow oven also suitable for lead-free soldering features a large material size and precisely controlled temperature profile.

Pick & Place system for accurately positioning SMT components on PCBs – from small chips to large QFPs.

THERMO MECHANICAL ANALYZER (TMA)

TMA SS 7100 /7300 from HITACHI HIGH TECH SCIENCE has super high sensitivity to determine the dimensional change of any solid, liquid or pasty material sample due to the increase of temperature and load. It can measure a wide range of samples, including thin film and small samples, because the total measurement method has no shape restrictions. Furthermore, the unit can be switched to push, penetration, bending or tension mode by simply exchanging the probe. A full line up of options, including an automatic cooling unit, ensures ease of use and highly accurate measurement.

TMA has the ability to make dynamic studies (DMA), with determination of elasticity, creep, and relaxation. The force applied may be constant, variable, modulated and combined. TMA has motion control by force or displacement.

Applications of thermal analysis: Thermal analysis for ceramic product design and other materials; Thermo constrictive stress measurement of shrink film; Temperature dependence of elastic modulus and broaden the information about thermo physical properties; effective in evaluating physical properties of film and fibre samples.

| MODEL | TMA7100 | TMA7300 |

| SAMPLE CYLINDER TEMPERATURE RANGE |

Quartz, metal -170 to 600°C |

Alumina Ambient to 1500°C |

| TMA MEASUREMENT RANGE TMA SENSITIVITY LOAD RANGE SCAN RATE |

±5mm 0.01µm ±5.8N 0.01 to 100°C/min |

|

| MAXIMUM SAMPLE SIZE | Expansion; Φ10xL25mm Tension; W1xT5xL25mm |

Expansion; Φ10xL25mm |

| SAMPLE LENGTH MEASUREMENT | Automated Measurement | |

THERMAL CONDUCTIVITY OF ECO MATERIALS

The Thermal Conductivity Test Tool λ-Meter EP500e (guarded hot plate apparatus) is a tool that uses the guarded hot plate method for the calculation of thermal conductivity, thermal transfer resistance as well as the k-value and U-value respectively of insulation materials, construction materials and other products.

The Thermal Conductivity Test Tool λ-Meter EP500e works in accordance with ISO 8302, EN 12667, ASTM C177, EN 1946-2, EN 12664, EN 12939, DIN 52612 and a high measurement accuracy as required by test authorities. Test are completed within a short measurement time.

The Thermal Conductivity Test Tool λ-Meter EP500e has been approved for use by test institutes or (higher education) institutes as well as for internal factory production control.

According to Appendix A of the European Insulating Standard EN 13162 … EN13171 the product developer has to submit at least 10 test results of thermal conductivity for CE-certification.

|

THERMAL PROPERTIES OF ECO MATERIALS

The Hot Disk TPS 2500 S is the flagship instrument in the system portfolio of Hot Disk AB. This general-purpose R&D instrument is designed for precision analysis of thermal transport properties – including thermal conductivity, thermal diffusivity and specific heat capacity. The TPS 2500 S covers an extensive range of materials of various geometries and dimensions, and meets ISO Standard 22007-2.

The standardized TPS technique – today used in more than 600 laboratories – is highly appreciated for its ability to simultaneously determine thermal conductivity, thermal diffusivity and specific heat capacity from a single measurement, with limited emphasis on sample preparation. The operative simplicity of the TPS 2500 S and the performance achieved when using optimally designed Hot Disk sensors, makes this system an ideal, trustworthy tool for tests of solids, liquids, powders, pastes and foams. The trademark high accuracy and precision also makes the instrument suitable for QC testing.

The Hot Disk Thermal Analyser software for the TPS 2500 S system incorporates tools for automated measurements as well as automatic temperature control of external devices. It also incorporates tools for exporting results to 3rd‐party software (MS Excel), for additional

processing or statistical analysis. For precise and automatic temperature readings the PT‐100 temperature sensor is available.

The Hot Disk Thermal Analyser software for the TPS 2500 S system incorporates tools for automated measurements as well as automatic temperature control of external devices. It also incorporates tools for exporting results to 3rd‐party software (MS Excel), for additional processing or statistical analysis. For precise and automatic temperature readings the PT‐100 temperature sensor is available.

|

||||||||||||||||||

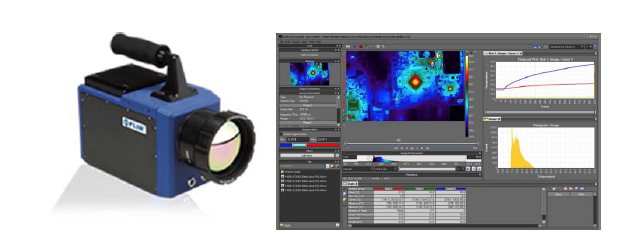

INFRA RED THERMOGRAPHY

The FLIR SC7600 is a very flexible camera, with the highest sensitivity, accuracy, spatial resolution and speed. Specifically designed for academic and industrial R&D applications as well as integrators who need to have a very flexible camera. The FLIR SC7600 provides for the first time the CNUC & Hypercal technologies which features NUC free operation and a large dynamic range choice.

The FLIR SC7600 gives complete flexibility in the optical path that needs to be followed for a specific application. This camera is available with small and wide optics.

The FLIR SC7600 is available with ResearchIR Max software to analyse infra‐red thermal measurements.

The FLIR SC7600 enables non‐contact temperature measurement, being useful for many applications, including but not limited to the following: surveying of buildings thermal efficiency, which might include detecting missing insulation in walls & ceilings, as well as identifying other potential areas where heat is being lost; identifying and reporting on potential electrical, mechanical & chemical faults in machinery, hardware, tooling and other infrastructure; aerial thermal surveys over urban areas; identifying necrosis with medical thermography, building draft‐proofing, computer vision systems, assess water stress in plants, research & development, and so on.

|

||||||||||||||||||||||||||||

SERVICES FOR THE CLUSTER OF ENVIRONEMENT

AIR QUALITY MEASURING MACHINE / EMISSION OF VOC PARTICLES

The versatile and flexible DANI MASTER GC (GAS CHROMATOGRAPH) is uniquely designed to perform conventional and fast gas chromatographic analyses fulfilling the demands of routine and research analyses over a variety of industries and applications such as environmental, 30 agriculture, food and beverage, flavor and fragrance, petrochemical, and pharmaceuticals among others.

The system can be equipped with an array of inlet systems and a wide selection of detectors, suitable for conventional and Fast GC analyses. The system integrates leading edge technology with total system control delivering outstanding reliability, repeatability, and performance. The most popular GC injector features an outstanding design and thanks to the patented DFC provides excellent precision in split, splitless, and pulsed injection modes of operation. In addition, the post‐injection carrier gas save mode is a valuable cost saving feature. To fulfil the users’ analytical needs a series of liner types are available, including liners suitable for SPME analysis.

The DANI MASTER TD (THERMAL DESORBER) offers superior sensitivity, versatility, and productivity for the extraction of volatile and semi‐volatile compounds from air and solid matrices. The MASTER TD performs an instantaneous heating of the trap through an ingenious built‐in device that assures the transfer of analytes as a narrow band into the GC column. In addition, backflush desorption of the trap further improves the efficiency of analyte transfer and permits the use of multi‐layer traps. The intuitive control through the TD Manager software offers a complete automated solution. The easy and flexible management of all operating parameters and analytical conditions permits unattended analysis of up to 50 samples

The DANI MASTER TD, combined with the DANI MASTER GC, is the right solution for air monitoring (indoor, workplace, and ambient air) and for the analysis of soil, polymers, packaging materials, etc.

The environmental concentrations of BTEX in the ambient air of major cities worldwide are of great concern. Ambient air measurements can be efficiently carried out by the MASTER TD equipped with a trap that selectively retains the target volatiles. The system fulfils productivity requirements and achieves sensitivity at ppb levels meeting specifications given in established U.S. EPA and international methods.

The Micro‐Chamber/ Thermal Extractor from MARKES INJTERNATIONAL is designed to meet the growing demand for fast emissions screening in manufacturing industry and third‐party test labs.

The Micro‐Chamber/ Thermal Extractor from MARKES INJTERNATIONAL offers a uniquely fast and cost‐effective quality control (QC) tool for screening the levels of volatile and semi‐volatile organic chemicals (VOCs and SVOCs) coming out of products and raw materials.

Demand for testing hazardous chemicals released (emitted) by construction products and consumer goods has seen rapid growth over recent years. This is driven by regulatory developments in Europe (Construction Product Directive/Regulation [CPD/R], Regulation, Evaluation, Authorisation and restriction of Chemical [REACH], German and French national laws, etc.), the US (the Ca Air Resources Board [CARB] formaldehyde rule, the international Green Construction Code [IgCC] initiative, etc.) and in the Far East (e.g. Chinese REACH). Some of the latest regulations require both third party certification and in‐house product quality control of emissions for full compliance. Typical sample types include wood‐based products,

plastic goods, insulation materials, electronics, foods, tobacco, decorative products, flooring materials, textiles and cleaning products.

The Micro‐Chamber/ Thermal Extractor from MARKES INJTERNATIONAL is used for both characterising overall emission (odour) profiles and for analysing the type and amount of individual chemicals coming out of each sample material.

ENVIRONMENTAL CLIMATE CHAMBER

The environmental climate chamber ACS DM600 has the essential environmental chamber performance and is specifically designed for General Purpose applications where excessively high temperatures or fast ramp rates are not required. They are ideal for climatic tests at steady states, and for use in a wide range of applications, such as tropical tests on pharmaceutical products, and a wide range of tests in the plastics, rubber, paper and semiconductor industries.

The environmental climate chamber ACS DM600 monitoring and management system (MyKratos) runs with mobile and desktop devices. The chamber wireless (WiFi) connection allows operation through various devices, such as tablets and smartphones (compatible with iOS 7 and Android 4.2.1). The operator interface can be remotely accessed also through the chamber connection to the client’s LAN or via GPRS/UMTS (upon activation of a SIM card data).

The environmental climate chamber ACS DM600 is prepared to do cooling tests according to standards: DIN 40046 page 3 test A, IEC 68‐2‐1 test A, BS2011 Part 2 test A, MILD‐STD 810 D Met. 502.2, MIL‐E 5272 Test 4.2.

32 The environmental climate chamber ACS DM600 is prepared to do hot tests according to standards: DIN 40046 page 4 test 3, IEC 68‐2‐2 test B, BS2011 Part 2 test B, MILD‐STD 810 D Met. 501.2, MILD‐STD 883 C Met. 1008.2, MIL‐E 5272 Test 4.1, MILD‐STD 202 E Met. 108 A. The environmental climate chamber ACS DM600 is prepared to do hot / cold tests according to standards: DIN 40046 page 14 test Nb, IEC 68‐2‐14 Nb, MILD‐STD 311 A Part 112.1. The environmental climate chamber ACS DM600 is prepared to do constant climate tests according to standards: DIN 40046, DIN 50014, IEC 68‐2‐3 test Ca, MILD‐STD 202 E Met. 103 B, DIN/IEC 68‐2‐56.

The environmental climate chamber ACS DM600 is prepared to do variable climate tests according to standards: DIN/IEC 68‐2‐30 DB, IEC 68‐2‐38, MILD‐STD 202 E Met. 106 D, MILD‐STD 883 C Met. 1004.4, DIN 40046 page 6 and 31, IEC 68‐2‐4 test D, BS 2011 Part 2.1 Test Da, MILD‐STD 750 B Met. 1021.1, DIN 40046 page 101, DIN 50016, MILD‐STD 311 A Part 105.1, MILD‐STD 810 Met. 507 Proc. 1‐2‐3.

|

||||||||||||||||||||||||||||||||||

ACCELERATED WEATHERING TESTERS

The QUV ACCELERATED WEATHERING TESTER reproduces the damage caused by sunlight, rain and dew. In a few days or weeks, the QUV can reproduce the damage that occurs over months or years outdoors.

The QUV ACCELERATED WEATHERING TESTER tests materials by exposing them to alternating cycles of UV light and moisture at controlled, elevated temperatures. The QUV simulates the effects of sunlight with fluorescent ultraviolet (UV) lamps, and it simulates dew and rain using condensing humidity and/or water spray. Types of damage include color change, gloss loss, chalking, cracking, crazing, hazing, blistering, embrittlement, strength loss and oxidation.

The QUV ACCELERATED WEATHERING TESTER is calibrated with a CR‐10 Calibration Radiometer which is an essential accessory to the QUV’s SOLAR EYE system because it ensures the accuracy of the SOLAR EYE and, ultimately, the QUV test results. One CR‐10 radiometer can calibrate any number of QUVs.

The QUV conforms to a large number of national, international and industry specifications, including but not limited to: ASTM D4799, ISO 11507, ASTM D6662, ISO 4892‐3, ASTM G154, SAE J2020, ASTM D4587, J15 K 5600‐7‐8, EN 927‐6 and AATCC TM186.

| MODEL | QUV ACCELERATED WEATHERING TESTER |

| TEMPERATURE RANGES LIGHT CYCLE TEMP.* | 45°C‐80°C |

| CONDENSATION CYCLE TEMP. | 40°C‐60°C |

| SPECIMEN CAPACITY STANDARD: | 50 Specimens, (75 x 150 mm) |

| SPECIMEN SUPPORT – SPECIAL IN STAINLESS STEEL | 1000x324x300 [mm] |

| ELECTRICAL: | 120/60,14A |

| WATER | 8 liter/day |

| LAMPS | UVA‐340 |

| LAMP LIFE: | 1600 hours (avg) |

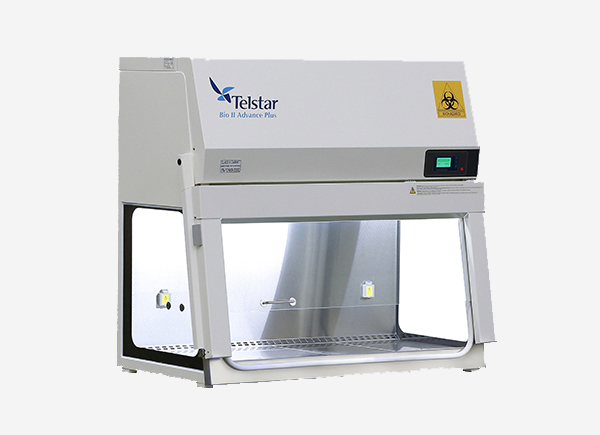

LAMINAR FLUX CHAMBER

The Telstar Bio II Advance series LAMINAR FLUX CHAMBER is a new generation of biological safety cabinets providing a compact design for easy installation within the laboratory. It has also been designed to the highest standards of safety, ergonomics, energy efficiency, reliability and ease of use in its class.

The Bio II Advance series is LAMINAR FLUX CHAMBER provide the market’s most secure safety cabinets for biological products.

The Bio II Advance series LAMINAR FLUX CHAMBER is certified by UNI EN ISO 9001:2000.

| MODEL | TELSTAR BIO II ADVANCE 4 |

| EXTERNAL DIMENSIONS, MM | 1354x759x1260 |

| INTERNAL DIMENSIONS, MM | 1259x605x587 |

| HEIGTH OF FRONT OPENING, MM | 200 |

| WEIGHT, KG | 200 |

| LAMINAR FLOW SPEED, M/S AND M3/H | 0.35 and 882 |

| FRONT ENTRY AIR SPEED / EXTRACTION FLOW RATE, M/S AND M3/H | 0.5 / 402 |

| POWER, KW | 1.3 |

| POWER SUPPLY , V / HZ | 230 / 50‐60 |

| LIGHTING LUX | > 1000 |

| SOUND, DB | <58 |

| VIBRATION, MM RMS | < 0.005 |